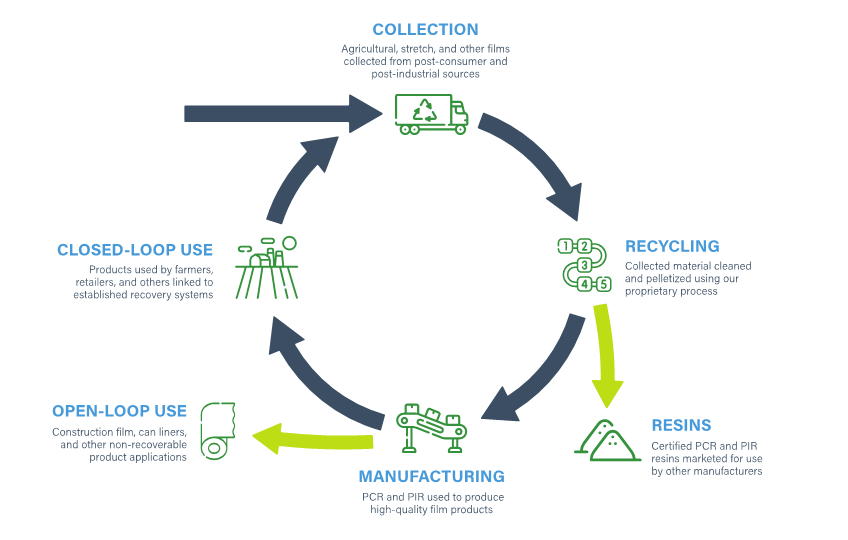

At Revolution, we collect, clean, and process post-consumer and post-industrial plastic film into high quality polyethylene resin ideal for use back in flexible film products.

Closed-Loop Production for Polyethylene Film (PE)

Closed-loop production and recycling represents a sustainable approach to material and energy usage that has the potential to transform the world’s economy and create circular economic systems that help preserve resources and reduce waste. Rather than creating new materials and disposing of them once they have served their designed purpose, closed-loop models emphasizes recovery and reuse of existing products or materials.

To put it another way: the traditional, linear manufacturing model thrives on the take, make, waste approach to production; whereas a closed-loop approach thrives on creating a sustainable cycle where materials can be recaptured as valuable source material and reused in the same or similar products again. Since all products are designed to have multiple life cycles instead of being disposable or single-use, the model creates significantly less waste and more efficiency. While no manufacturing system is perfect (especially when it comes to addressing environmental concerns), closed-loop production and recycling has distinct advantages over the linear manufacturing model and can be applied across nearly every industry from agriculture to commercial packaging.

At Revolution, we’ve built our business with a circular, closed-loop approach to manufacturing and recycling for over 30 years. Which is why we’re able to deliver high-quality, effective, sustainable solutions for plastic film across a broad spectrum of products and markets. From products containing the highest amounts of PCR resin possible to custom closed-loop programs tailored to our customers’ business, we’re committed to empowering everyone to contribute to a more sustainable future.